The construction binding wire production line can also be called small electro-galvanized wire production line, and the wire diameter is usually in the range of 0.6-1.2 mm.

The finished wire is low in price, has good flexibility and is not easy to break. It is one of the most ideal binding wires in the construction industry, mainly using low-zinc cold-plated iron wire.

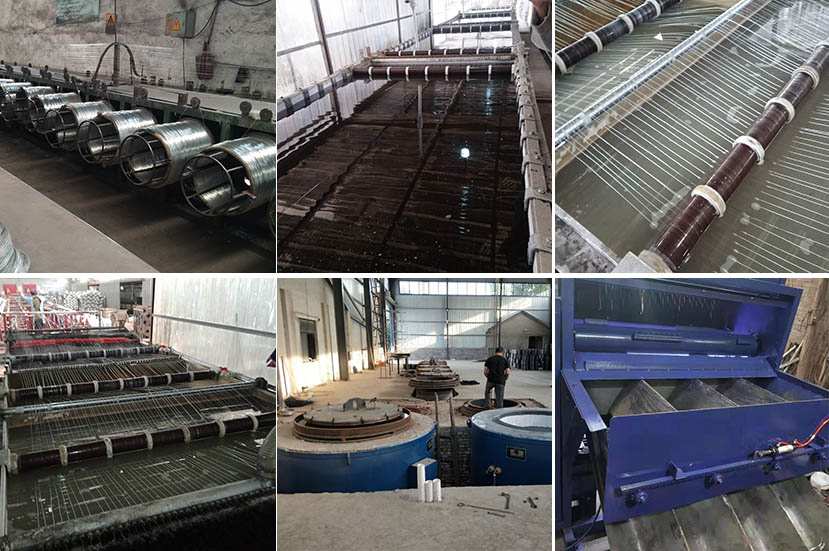

The new small electroplating production line is a pollution-free, energy-saving and environmentally friendly galvanized iron wire production line, including wire arrangement, wire surface cleaning device, electroplating device, air drying device, drying device and wire. The collection device, as well as the pollution-free, energy-saving and environmentally friendly galvanized iron wire proposed by the utility model, proposes a complete wire production line, which can automatically complete the complete production of the wire, including wire feeding, straightening, rust removal, dust removal, galvanizing, and pneumatic Dry, clean and wire. The whole process is fully automatic and does not require labor. Compared with the existing manual mode, it saves time and efficiency. The whole process is pollution-free production, effectively preventing environmental pollution.

USD32000-USD58000

Well type resistance furnace is a cycle-operated electric furnace for quenching, tempering and annealing of steel parts. It is especially suitable for iron wire recrystallization and annealing. The advantage of energy-saving electric furnace is that the lining is composed of needle-punched fiber blanket preforms, with small heat absorption coefficient and electric heating The components are suspended in the furnace, fully exposed and directly radiated, with high thermal efficiency, and energy saving by more than 30% compared with traditional electric furnaces.

点击空白处返回

![]()

- Description